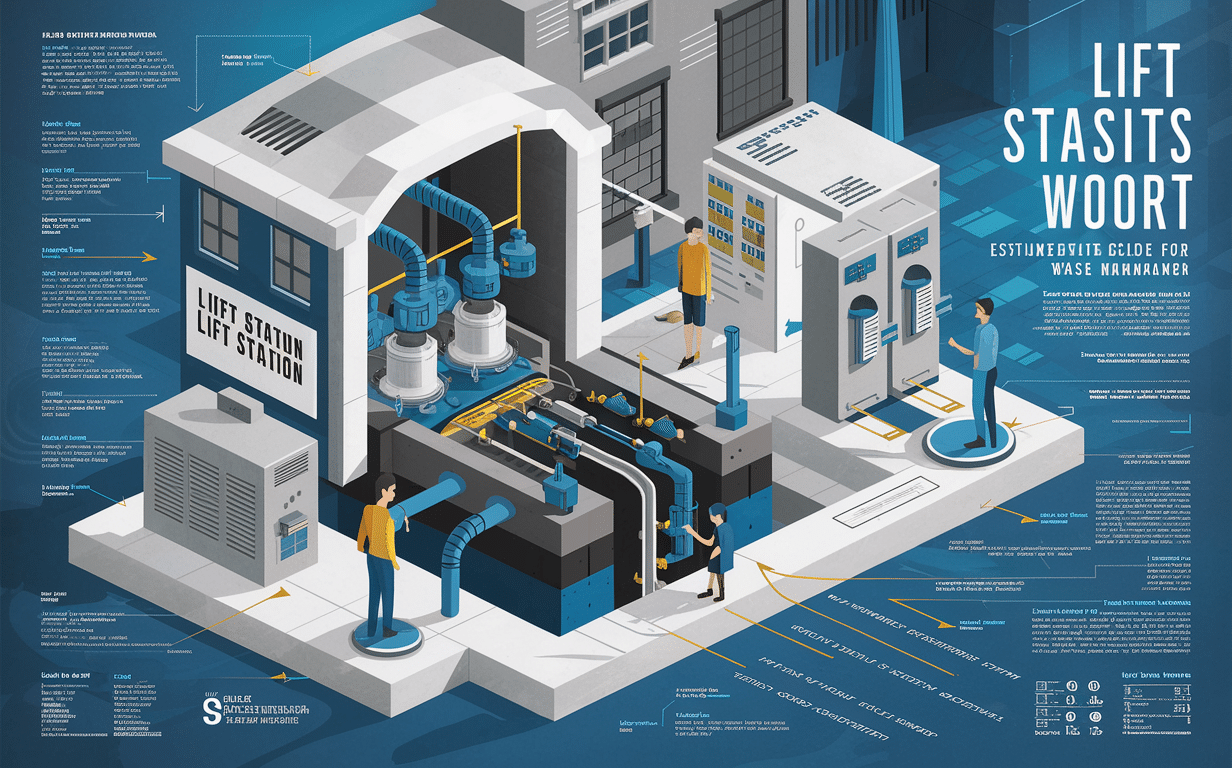

How Lift Stations Work: Essential Guide for Waste Management

When it comes to waste management, understanding how lift stations work is crucial. These systems are vital for transporting wastewater in areas where gravity alone can’t do the job.

Key Takeaway

- Lift stations are designed to move wastewater from lower to higher elevations, especially in areas where gravity flow isn’t feasible.

- Key components include submersible pumps, wet wells, and alarm systems.

- Regular maintenance is essential for the longevity and proper functioning of lift stations.

- Video inspections can help detect and resolve issues early on.

Lift stations are mechanical systems designed to transport wastewater from lower to higher elevations. This is particularly useful in areas where the landscape prevents the natural gravitational flow of sewage.

These systems are indispensable in both urban and rural settings, ensuring efficient waste management and environmental safety.

The Basics of Lift Stations

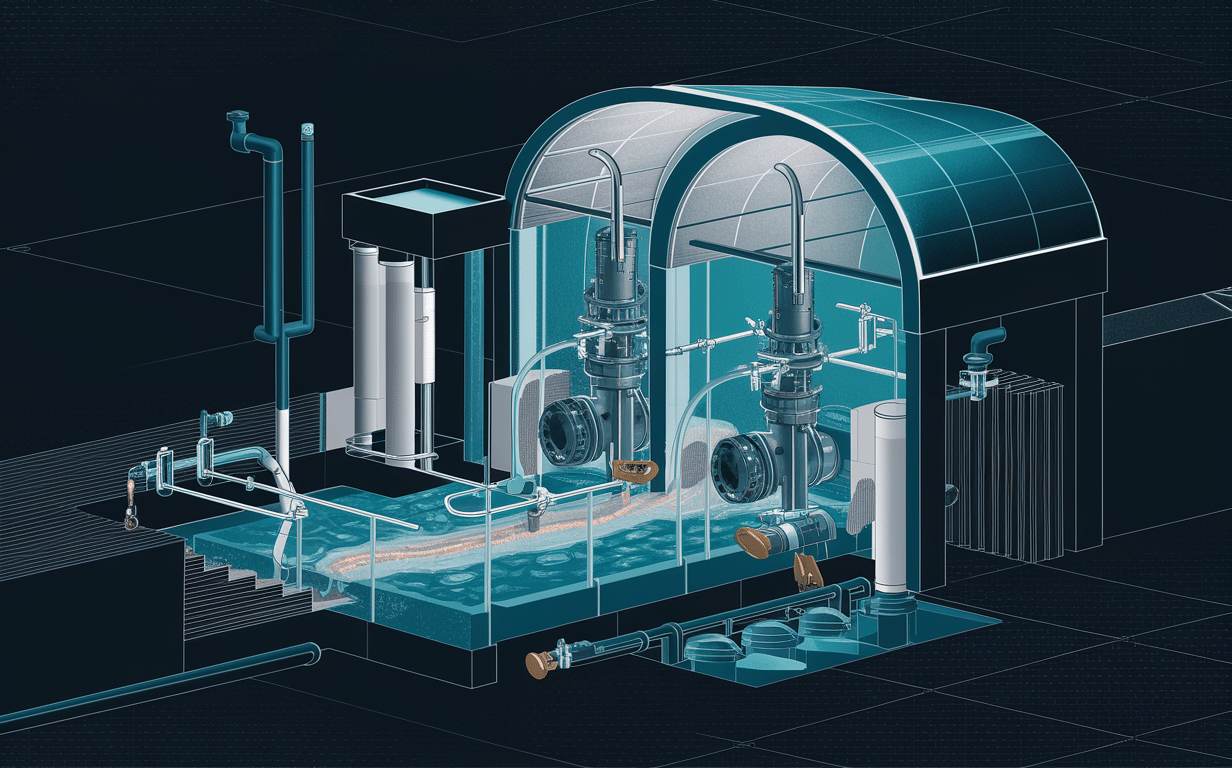

How Lift Stations Work

Lift stations work by employing pumps to “lift” wastewater from a lower elevation to a higher one. The main components include a wet well (a holding tank for wastewater), pumps, control systems, and alarms.

Key Components

- Wet Well: This is the holding tank where wastewater is collected.

- Submersible Pumps: These are placed in the wet well and are responsible for pumping the wastewater upward.

- Control Systems: These monitor the levels in the wet well and activate the pumps when needed.

- Alarms: These alert operators to any malfunctions or issues within the system.

Importance of Lift Stations

Lift stations play a critical role in modern waste management by enabling efficient wastewater transportation in areas where gravity flow is not possible. This ensures that wastewater is effectively treated and disposed of, protecting public health and the environment.

Types of Lift Stations

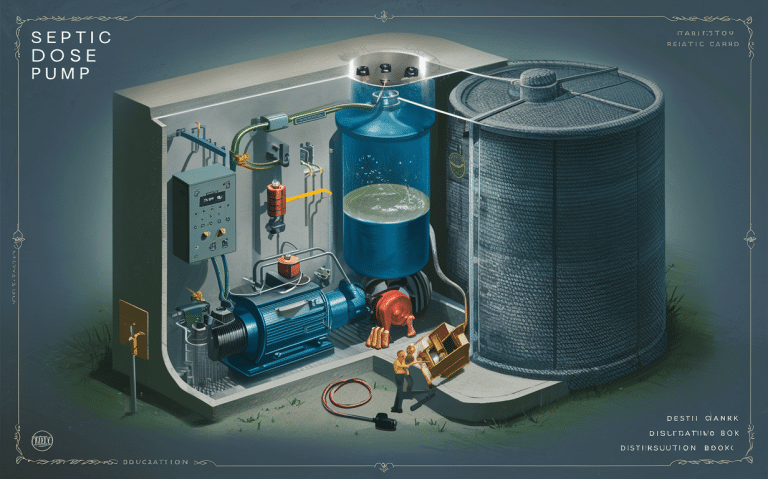

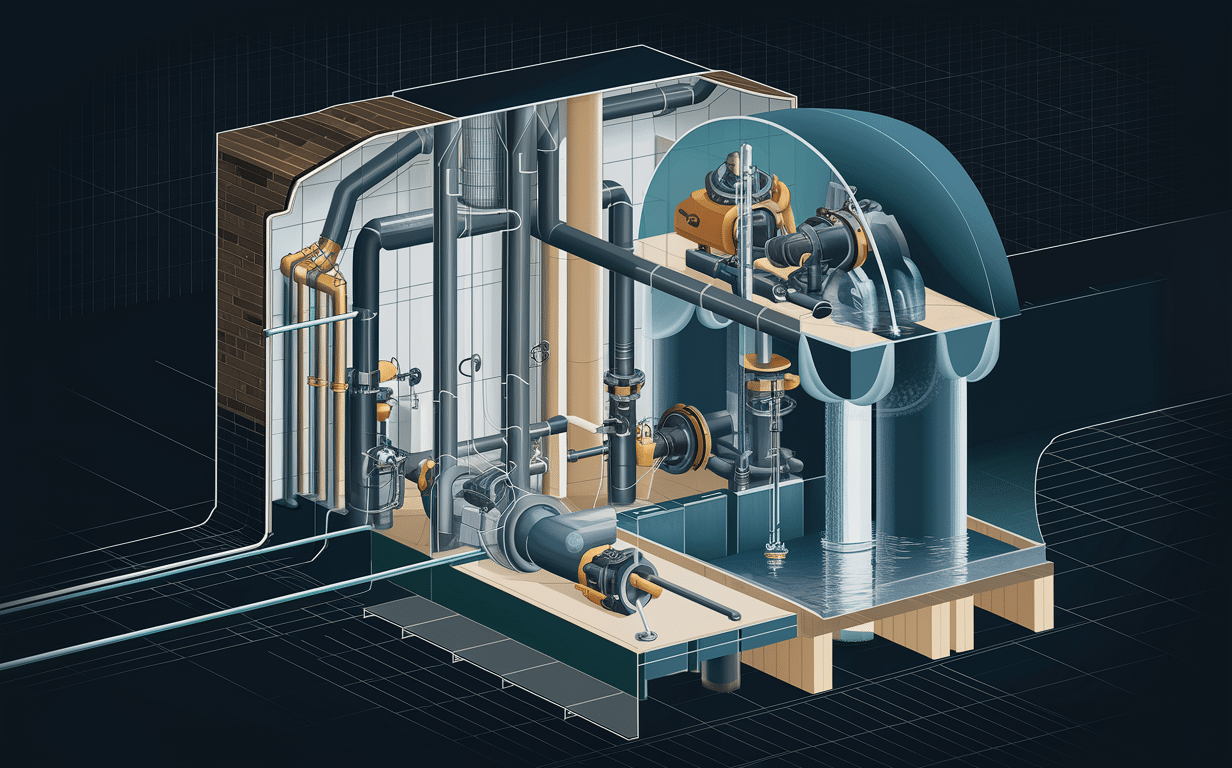

Dry Well Lift Stations

In dry well lift stations, pumps and electrical equipment are housed in a separate, dry chamber adjacent to the wet well. This setup allows for easier maintenance and reduces the risk of equipment damage due to water exposure.

Wet Well Lift Stations

In these systems, the pumps are submerged in the wet well. These are more compact and are generally easier to install, although maintenance can be more challenging due to the underwater environment.

Common Issues and Maintenance

Clogging

Lift stations can experience clogs due to the accumulation of debris and grease. Regular cleaning and maintenance can help prevent this issue.

Pump Failures

Pumps can fail due to wear and tear or electrical issues. Regular inspections and timely replacements are essential to avoid system breakdowns.

Common Lift Station Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Clogging | Accumulation of debris | Regular cleaning |

| Pump Failure | Wear and tear, electrical | Routine inspections, replacement |

| Alarm Failure | Electrical issues | Regular testing |

| Odor Problems | Stagnant water | Regular pumping, cleaning |

Advanced Monitoring Systems

Modern lift stations are equipped with advanced monitoring systems. These systems use real-time data and remote monitoring to ensure that everything operates smoothly.

SCADA Systems

Supervisory Control and Data Acquisition (SCADA) systems are used to monitor and control lift stations remotely. These systems provide real-time data and alerts, enabling operators to respond quickly to any issues.

Benefits of SCADA Systems in Lift Stations

| Benefit | Description |

|---|---|

| Real-time Monitoring | Provides up-to-date information on system status |

| Remote Control | Allows operators to manage the system remotely |

| Data Logging | Records operational data for analysis |

| Alarms and Alerts | Immediate alerts for any issues |

| Predictive Maintenance | Helps predict and prevent failures |

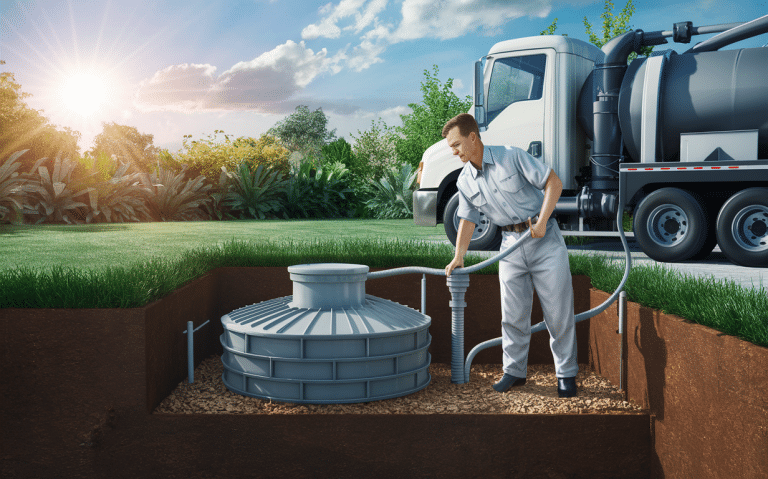

The Role of Video Inspections

Video inspections are an invaluable tool for maintaining lift stations. These inspections allow for a close-up look at the internal components of the system, helping to identify any issues before they become major problems.

Real-Life Applications

Urban Settings

In cities, lift stations are used to manage wastewater in areas where the terrain is uneven. This ensures efficient waste removal and minimizes the risk of sewage backups.

Rural Areas

In rural areas, lift stations are used to transport wastewater to treatment facilities, ensuring that even remote locations have access to efficient waste management services.

- Lift stations are essential components of wastewater collection systems, responsible for lifting sewage from lower lying areas to transport it for treatment and disposal (EPA).

- The average lift station contains one to three pumps, with each pump capable of moving 1,000 to 5,000 gallons of wastewater per minute (Gravity Flow).

- Lift stations use various types of pumps, including submersible, grinder, and ejector pumps, depending on the specific requirements of the wastewater being lifted (Gravity Flow).

- The average lift station operates continuously, with the pumps cycling on and off to maintain a consistent flow in the collection system (EPA).

- Lift stations require regular maintenance to ensure proper functioning, including inspections, cleaning, and repairs (Gravity Flow).

- In the United States, there are approximately 150,000 lift stations in operation, serving communities with populations ranging from less than 1,000 to over 1 million people (EPA).

Best Practices for Maintaining Lift Stations

- Regular Inspections: Conduct routine inspections to identify and address any issues early on.

- Scheduled Maintenance: Follow a maintenance schedule to keep all components in good working order.

- Use of Advanced Monitoring Systems: Implement advanced monitoring systems like SCADA to keep tabs on the lift station’s performance.

- Staff Training: Ensure that your team is well-trained in operating and maintaining lift stations.

- Emergency Preparedness: Have a plan in place for emergency situations, including backup pumps and power supplies.

Key Takeaways: How Lift Stations Work

- Understand Your System: Familiarize yourself with the components and operations of your lift station.

- Monitor Performance: Use monitoring systems to keep track of the lift station’s performance.

- Invest in Maintenance: Regular maintenance can prevent costly repairs and extend the lifespan of your lift station.

- Stay Informed: Keep up-to-date with the latest advancements in lift station technology and best practices.

What Sets United Sewer & Septic Apart

At United Sewer & Septic, we bring over 30 years of experience in the septic and sewer industry. Our expertise extends to the installation, maintenance, and repair of lift stations, ensuring that your system operates efficiently and reliably.

Our team is equipped with advanced tools and technology, including video inspection systems, to provide comprehensive lift station services. We are committed to delivering high-quality workmanship and exceptional customer service, making us a trusted partner for all your septic and sewer needs.

Conclusion

Understanding how lift stations work is essential for anyone involved in waste management. These systems play a crucial role in transporting wastewater, especially in areas where gravity flow isn’t possible. By familiarizing yourself with the components, maintenance requirements, and advanced monitoring systems, you can ensure the efficient operation of your lift station.

For expert lift station services, look no further than United Sewer & Septic. With our experienced team and state-of-the-art equipment, we are here to help you every step of the way. Contact us today to learn more about our services and how we can assist you with your lift station needs.

By following these guidelines, you can ensure that your lift station operates efficiently and reliably, providing effective waste management for your community.