Essential Preventive Measures for Lift Station Reliability in Septic Systems

Preventive Measures for Lift Station Reliability in septic systems. Learn maintenance tips to avoid costly repairs and ensure efficiency.

Preventive Measures for Lift Station Reliability in septic systems. This guide outlines practical steps to ensure your lift station operates smoothly and avoids costly repairs.

Whether you’re a homeowner, business owner, or property manager, understanding these strategies will help you maintain the efficiency and longevity of your septic system.

Key Takeaway

- Regular maintenance is vital for lift station reliability.

- Inspections and monitoring help identify issues early.

- Pump and electrical system checks are critical.

- Emergency response protocols are essential for minimizing downtime.

- Professional services are recommended for thorough maintenance.

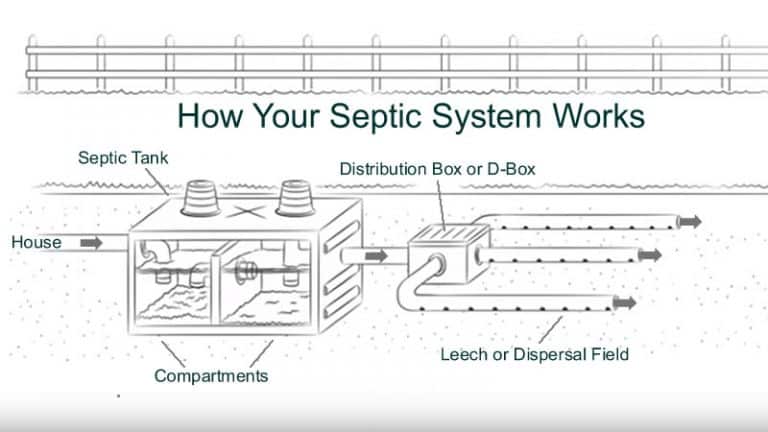

Lift Stations are an integral part of septic and sewer systems. They transport wastewater from lower to higher elevations, ensuring smooth flow to treatment plants. Lift stations can fail without proper maintenance, leading to backups, overflows, and environmental hazards.

Importance of Preventive Measures for Lift Station Reliability in Septic Systems

Regular maintenance keeps Preventive Measures for Lift Station Reliability. Scheduled checkups can prevent minor issues from becoming significant problems. Maintenance includes inspecting pumps, electrical systems, and float switches. It also involves cleaning wet wells and other components.

1. Inspection and Monitoring

Frequent inspections help identify potential problems early. Monitoring systems can alert you to issues such as pump malfunctions or high water levels. Installing sensors and alarms can enhance your lift station’s reliability.

2. Pump and Electrical System Checks

Pumps are the heart of lift stations. Regular checks ensure they are functioning correctly. Electrical systems should also be inspected to prevent failures. Faulty wiring or control panels can disrupt operations.

3. Emergency Response Protocols

Having a plan for emergencies can minimize downtime and damage. Know who to call for repairs and have backup equipment ready. A quick response can prevent extensive damage and costly repairs.

4. Benefits of Preventive Maintenance

Preventive maintenance not only extends the life of your lift station but also saves money in the long run. It reduces the risk of emergency repairs and environmental penalties. A well-maintained system is more efficient and reliable.

5. Professional Services

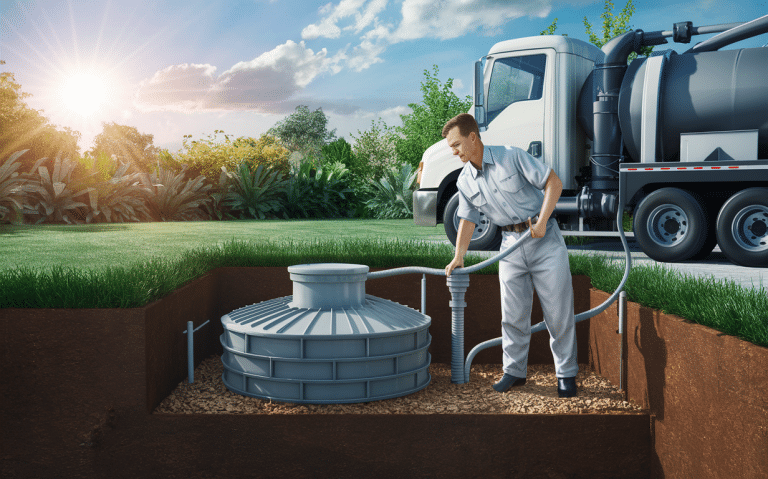

While some maintenance tasks can be performed in-house, professional services are recommended for comprehensive inspections and repairs. Experts have the tools and knowledge to identify and fix issues you might miss.

Detailed Steps for Lift Station Maintenance

Cleaning and Debris Removal

Regular cleaning prevents buildup that can clog pumps and pipes. Debris and sediment should be removed from wet wells and other components. This task is crucial for maintaining efficient operations.

| Task | Frequency | Importance Level |

|---|---|---|

| Wet well cleaning | Monthly | High |

| Debris removal | Bi-weekly | High |

| Pump cleaning | Monthly | High |

| Electrical inspections | Quarterly | Medium |

Checking and Adjusting Pumps

Pumps should be checked for wear and tear. Adjustments may be needed to ensure they are operating at peak efficiency. Regular testing can identify issues before they cause failures.

Testing and Monitoring Systems

Testing sensors and alarms ensure they are functioning correctly. Monitoring systems provide real-time data on lift station performance, helping you respond quickly to any issues.

Common Problems and Solutions

Understanding common lift station problems can help you address them promptly. Issues like pump failures, electrical malfunctions, and sensor errors can disrupt operations.

Pump Failures

Pump failures can be caused by blockages, wear, or electrical issues. Regular maintenance can prevent these problems. If a pump fails, it should be repaired or replaced immediately.

Electrical Malfunctions

Electrical issues can cause pumps to stop working. Regular inspections can identify faulty wiring or control panels. Repairs should be performed by qualified professionals.

Sensor Errors

Sensors can fail due to dirt, wear, or electrical issues. Regular cleaning and testing can prevent these problems. Replacing faulty sensors promptly is crucial for maintaining lift station reliability.

DIY vs. Professional Maintenance

Some maintenance tasks can be performed by property owners, while others require professional expertise. Understanding the difference can help you decide when to call in the experts.

DIY Maintenance Tasks

- Visual inspections: Look for signs of wear or damage.

- Cleaning: Remove debris from wet wells and pumps.

- Basic repairs: Fix minor issues like loose connections.

Professional Maintenance Services

- Comprehensive inspections: Identify issues you might miss.

- Advanced repairs: Fix complex problems.

- System upgrades: Improve lift station efficiency and reliability.

Cost-Benefit Analysis of Preventive Maintenance

Investing in preventive maintenance can save money in the long run. While there are upfront costs, the benefits include reduced emergency repairs, longer system life, and improved efficiency.

| Preventive Measure | Cost Estimate | Potential Savings | Return on Investment |

|---|---|---|---|

| Regular inspections | $200-$500 | $1,000-$3,000 | High |

| Pump maintenance | $300-$700 | $2,000-$4,000 | High |

| Electrical system checks | $150-$400 | $1,500-$3,500 | High |

| Sensor monitoring systems | $500-$1,000 | $3,000-$5,000 | High |

Environmental Impact

Proper maintenance of lift stations also has environmental benefits. It reduces the risk of overflows and contamination, protecting local ecosystems and water sources.

Legal and Regulatory Compliance

Maintaining your lift station is not just about efficiency. It’s also about compliance with local and federal regulations. Regular maintenance helps you avoid fines and legal issues.

Training and Knowledge

Educating your team about lift station maintenance can improve efficiency and reliability. Training programs can teach them how to perform basic inspections and identify potential issues.

Conclusion

Preventive measures for lift station reliability are essential for maintaining efficient septic systems. Regular maintenance, inspections, and professional services can prevent failures and extend the life of your lift station.

Investing in preventive measures saves money in the long run and protects the environment. Only work with trusted and well-experienced professionals, call us at (888) 845-CLOG (2564) or (845) 637-3544 for your free estimate or for any emergency services!

Key Takeaways

- Regular maintenance is crucial for reliable lift station operations.

- Inspections and monitoring help identify issues early.

- Pump and electrical system checks are necessary for optimal performance.

- Emergency response protocols minimize downtime and damage.

- Professional services ensure thorough maintenance and compliance.

By following these preventive measures, you can ensure your lift station remains reliable and efficient for years to come.