Preventing Sewer Line Clogs and Blockages with Grease Trap Maintenance: Essential Tips

Preventing sewer line clogs and blockages with grease trap maintenance ensures smooth plumbing, cost savings, and compliance. Learn more today!

Preventing sewer line clogs and blockages starts with regular grease trap maintenance. Grease traps are essential for keeping fats, oils, and grease (FOG) from entering the sewer system, which can cause severe clogs and blockages. By maintaining your grease trap, you can avoid costly repairs and ensure a smoothly running plumbing system.

Key Takeaway

- Grease traps are crucial for preventing sewer line clogs by capturing FOG.

- Regular maintenance of grease traps is necessary for effective sewer system function.

- Proper grease trap maintenance can prevent expensive and disruptive sewer line blockages.

- Simple habits and professional services can significantly aid in keeping sewer lines clear.

Preventing Sewer Line Clogs and Blockages with Grease Trap Maintenance

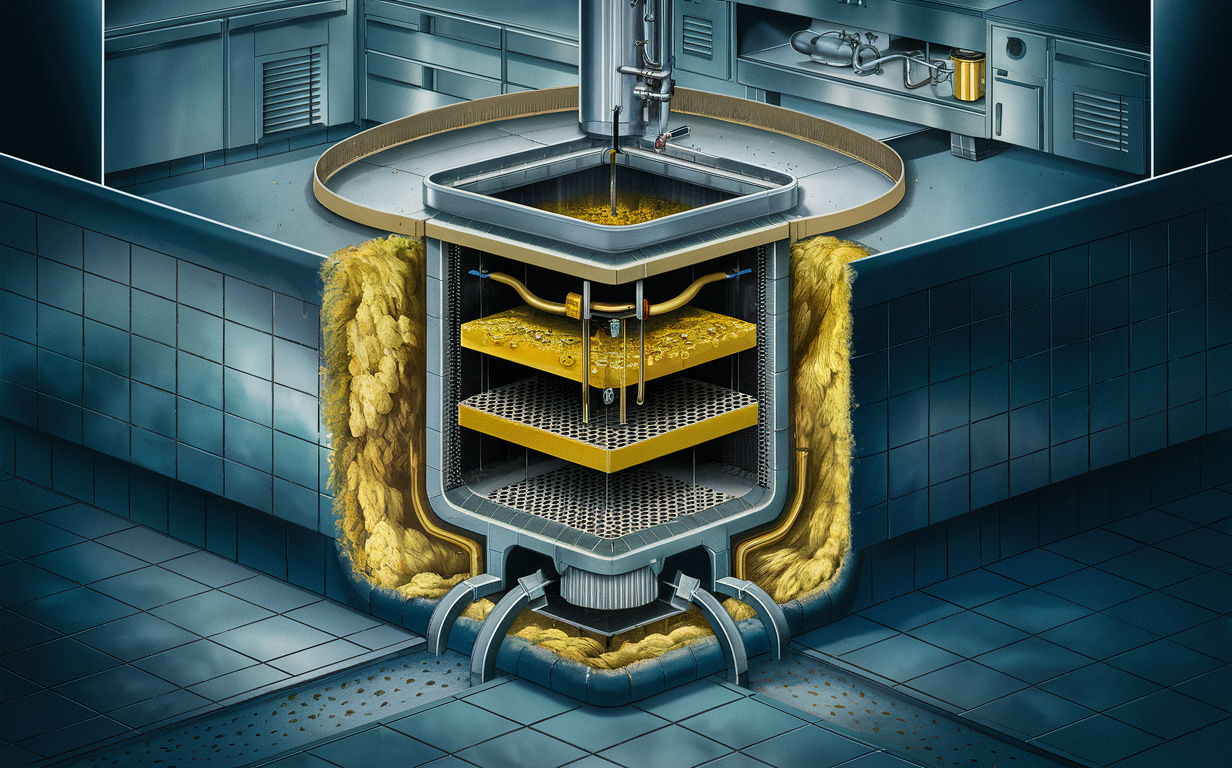

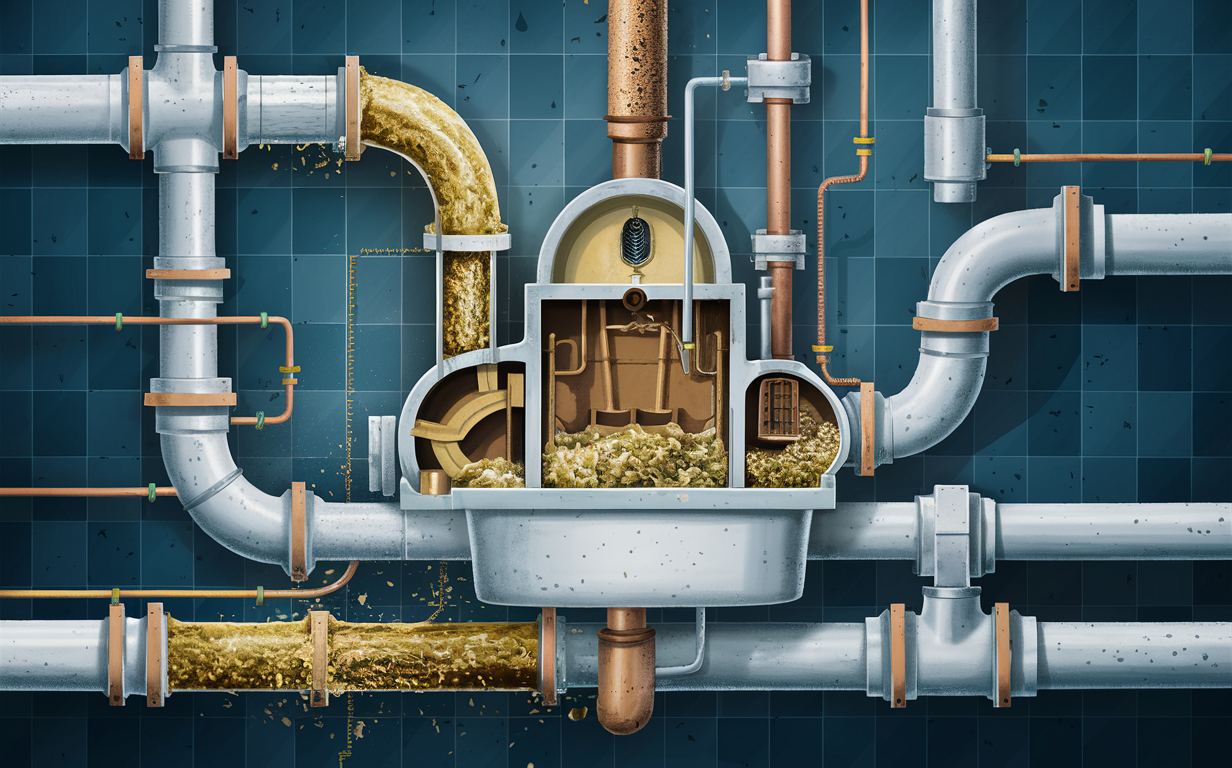

How Grease Traps Prevent Sewer Line Clogs

Grease traps work by capturing FOG before it enters the sewer system. When FOG accumulates in the pipes, it solidifies and creates blockages. By using a grease trap, you ensure that only water flows through the pipes, minimizing the risk of clogs.

Importance of Regular Maintenance

Why Grease Trap Maintenance Matters

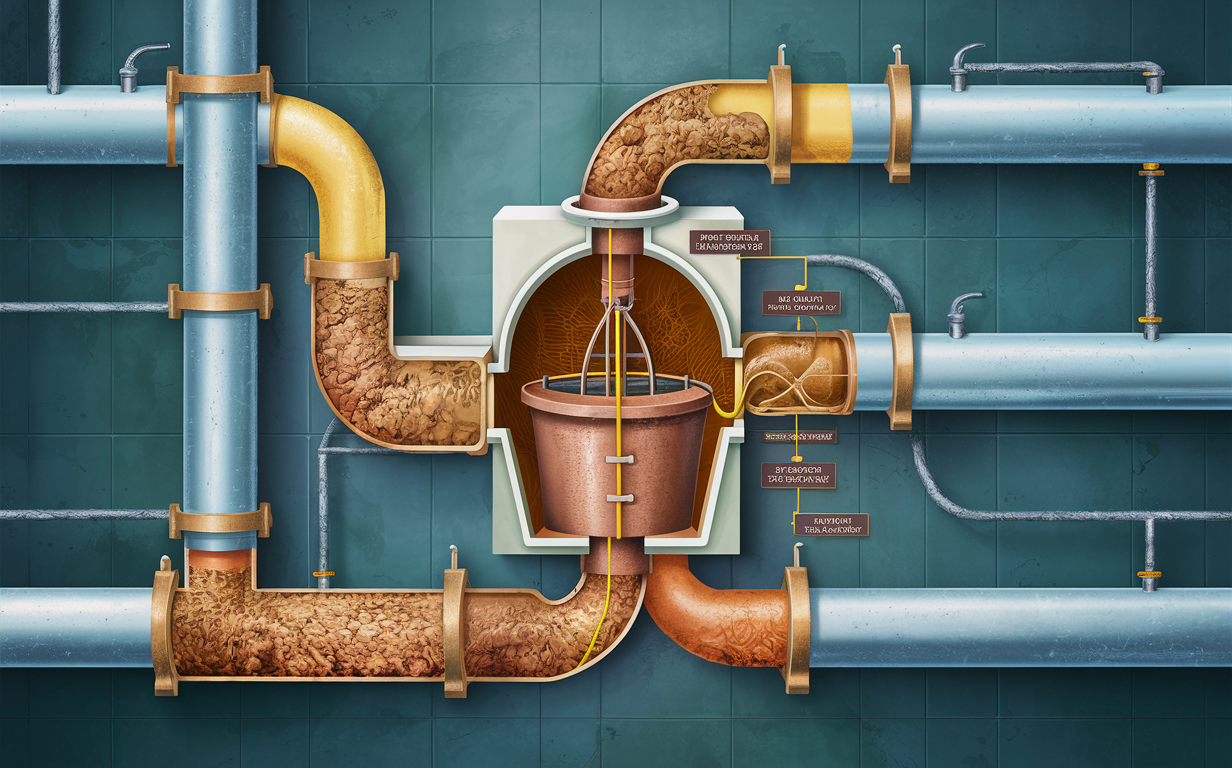

Regular maintenance of grease traps ensures that they function correctly. Neglecting maintenance can lead to overflow, which allows FOG to enter the sewer lines, causing clogs and blockages.

Consequences of Ignoring Maintenance

Ignoring grease trap maintenance can result in severe blockages that might require extensive repairs. This can lead to downtime for businesses, especially for food service establishments, causing significant losses.

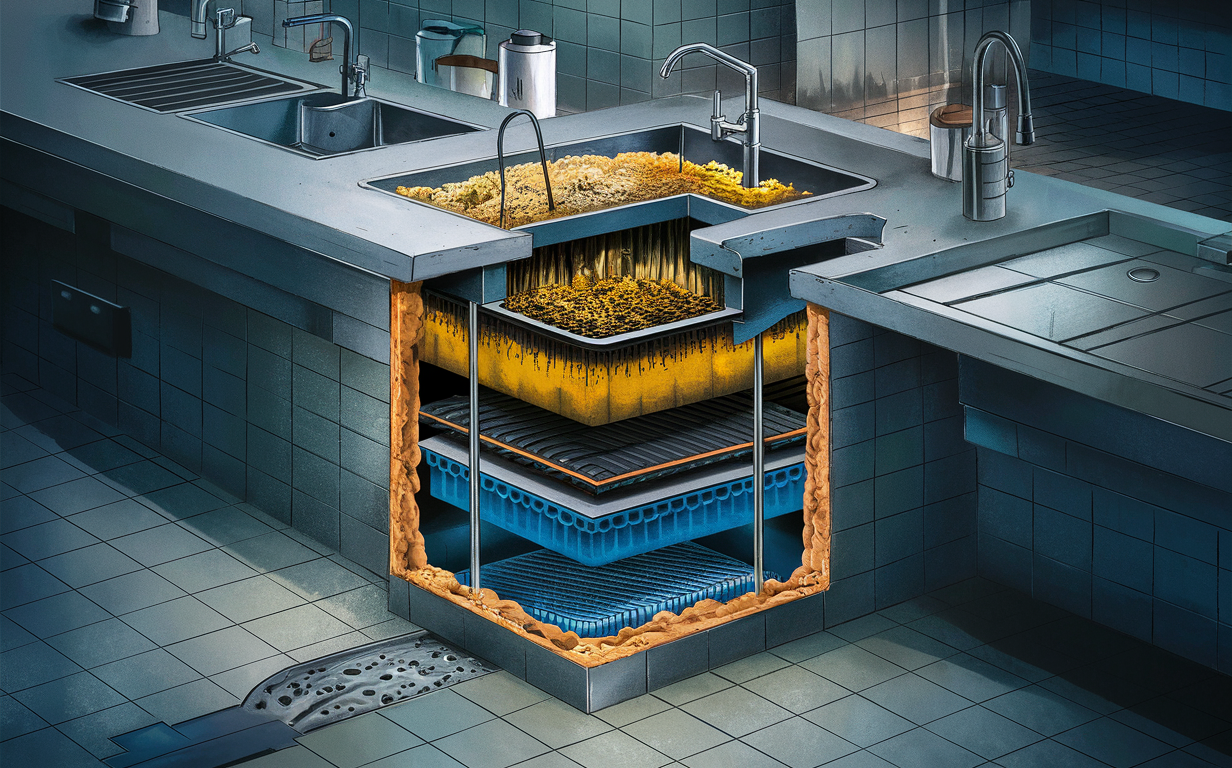

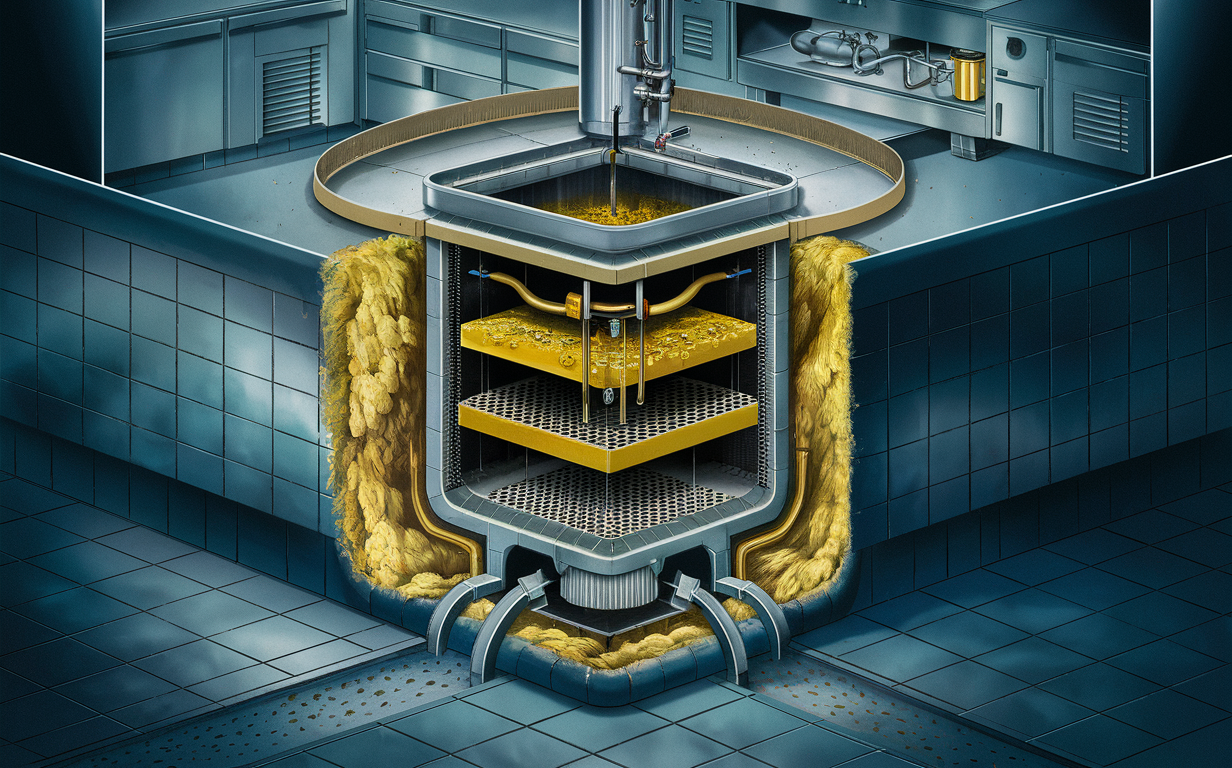

Steps to Maintain Your Grease Trap

Daily and Weekly Cleaning

- Daily maintenance: Scrape and wipe down cooking equipment to remove excess grease before washing.

- Weekly maintenance: Check the grease levels and remove any accumulated grease from the trap.

Professional Cleaning

Hiring professionals for regular grease trap cleaning ensures that all parts of the trap are thoroughly cleaned and any potential issues are identified early.

Monitoring and Record-Keeping

Keep a log of maintenance activities and monitor grease levels. This helps in scheduling timely maintenance and prevents overflow.

Grease Trap Maintenance Schedule

| Maintenance Task | Frequency | Responsible Party |

|---|---|---|

| Scraping cooking equipment | Daily | Kitchen Staff |

| Checking grease levels | Weekly | Maintenance Team |

| Professional cleaning | Monthly/Quarterly | Licensed Service Provider |

| Record keeping | Ongoing | Facility Manager |

Signs of a Clogged Grease Trap

Slow Draining

One of the first signs of a clogged grease trap is slow draining sinks or floor drains. This indicates that FOG has started to block the pipes.

Foul Odors

A foul smell coming from the drains can indicate that the grease trap is full or clogged, causing decomposition of trapped FOG.

Overflow

If grease or water is overflowing from the grease trap, it’s a clear sign that immediate maintenance is needed.

Preventive Measures for Optimal Performance

Employee Training

Educate your staff about the importance of scraping off grease before washing and proper disposal of food waste. This reduces the amount of FOG that enters the grease trap.

Proper Disposal Methods

Encourage the use of disposal bins for greasy waste and food scraps. Avoid pouring grease directly into sinks.

Tips for Effective Grease Trap Maintenance

- Schedule regular professional cleanings.

- Monitor grease levels frequently.

- Educate staff on proper grease disposal.

- Keep a detailed log of maintenance activities.

- Invest in high-quality grease traps and cleaning services.

Benefits of Preventive Maintenance

Cost Savings

Regular maintenance reduces the risk of severe blockages and the need for expensive emergency repairs.

Longevity of Plumbing Systems

Properly maintained grease traps extend the life of your plumbing systems by preventing FOG-related damage.

Compliance with Regulations

Many local regulations require businesses to maintain their grease traps to prevent environmental contamination. Staying compliant avoids fines and legal issues.

Cost Comparison of Regular Maintenance vs. Emergency Repairs

| Maintenance Task | Frequency | Estimated Cost |

|---|---|---|

| Professional Cleaning | Monthly/Quarterly | $150 – $300 |

| Emergency Repair Service | As needed | $500 – $2000+ |

| Plumbing Replacement | As needed | $1000 – $5000+ |

According to the Environmental Protection Agency (EPA), fats, oils, and greases (FOGs) are the leading cause of sewer line clogs and blockages in the United States (EPA, 2021).

The National Restaurant Association reports that restaurants are responsible for 60% of all FOG-related sewer overflows (NRA, 2021).

Grease traps are essential in preventing FOGs from entering the sewer system. The Food and Agriculture Organization (FAO) of the United Nations states that grease traps can capture up to 90% of the FOGs produced by a commercial kitchen (FAO, 2018).

The National Sanitation Foundation (NSF) recommends that grease traps be cleaned and serviced every 90 days for restaurants and every 180 days for other food service establishments (NSF, 2021).

The cost of grease trap cleaning and maintenance varies depending on the size of the establishment and the frequency of service. The average cost for a small grease trap is between $100 and $300 per cleaning (HomeAdvisor, 2021).

Properly maintaining grease traps can save businesses money in the long run. The EPA estimates that businesses can save up to $3,000 per year by preventing sewer line backups and related damages (EPA, 2021).

Professional Services vs. DIY Maintenance

Pros and Cons of Professional Services

- Pros: Thorough cleaning, early issue detection, compliance assurance.

- Cons: Cost if done excessively.

DIY Maintenance Tips

- Regularly check and remove grease.

- Keep maintenance logs.

- Train staff on proper disposal methods.

The Role of Technology in Grease Trap Maintenance

Smart Grease Traps

Modern grease traps come with sensors that alert you when cleaning is required, ensuring timely maintenance.

Video Inspections

Using video inspections helps in identifying blockages and ensures that the grease trap is functioning correctly.

Environmental Impact

Reducing Environmental Contamination

Proper grease trap maintenance prevents FOG from entering the sewer system and waterways, protecting the environment.

Sustainability Practices

Implementing sustainable practices in grease disposal and maintenance contributes to environmental conservation efforts.

Frequently Asked Questions

How often should I clean my grease trap?

It depends on usage, but generally, it’s recommended to have a professional cleaning at least quarterly.

Can I clean the grease trap myself?

Yes, basic cleaning can be done by staff, but professional cleaning is recommended for thorough maintenance.

What happens if I don’t maintain my grease trap?

Neglecting maintenance can lead to severe blockages, costly repairs, and potential regulatory fines.

Key Takeaway

Maintaining your grease trap is crucial for preventing sewer line clogs and blockages. Regular maintenance not only saves costs but also ensures the longevity of your plumbing systems and compliance with local regulations. Implementing simple habits and scheduling professional services can make a significant difference in keeping your sewer lines clear.

By adhering to these practices, you’ll reap the benefits of a smoothly running plumbing system, reduced risk of blockages, and a clean, compliant business environment. Make grease trap maintenance a priority to avoid the hassles and costs associated with sewer line clogs.

For professional grease trap maintenance and other septic and sewer services, contact United Sewer & Septic. Our experienced team is ready to help keep your plumbing systems in top shape. Call us today at (845) 637-3544 or visit our website to schedule service.