Essential Guide: Accessing and Opening the Grease Trap for Pumping

Accessing and opening the grease trap for pumping ensures efficient kitchen operations. Learn maintenance tips to prevent FOG buildup and plumbing issues.

Accessing and opening your grease trap for pumping is a crucial task for maintaining efficient kitchen operations and preventing plumbing issues. Proper grease trap maintenance ensures that your plumbing system remains clear of blockages caused by fats, oils, and grease (FOG).

This guide provides a comprehensive guide on how to access and open your grease trap for effective pumping.

Key Takeaway

- Grease traps are essential for preventing FOG from entering the plumbing system.

- Regular maintenance and pumping help avoid costly repairs and downtime.

- Understanding the structure and operation of your grease trap can simplify the maintenance process.

- Following a systematic approach ensures efficient and safe grease trap cleaning.

Understanding the Importance of Grease Trap Maintenance

Grease traps are installed in commercial kitchens to intercept FOG before they can clog the plumbing system. Accessing and Opening the Grease Trap for Pumping is essential as, over time, grease traps accumulate waste, reducing their effectiveness. Regular pumping and cleaning are necessary to keep them functioning properly.

Accessing and Opening the Grease Trap for Pumping

Identifying Your Grease Trap Location

The first step in maintaining your grease trap is to locate it. Grease traps are typically installed under sinks or in the basement. Ensure you have easy access and sufficient space to perform the maintenance tasks.

Accessing and Opening the Grease Trap for Pumping involves removing the lid, which may be secured with screws or clips. Use appropriate tools to safely open the trap without damaging components

Tools You Will Need

To access your grease trap, you will need the following tools:

- Wrench or screwdriver (depending on the type of cover)

- Rubber gloves

- Safety goggles

- Container for disposing of grease and waste

- Cleaning brush

Opening The Grease Trap

Step-by-Step Process

- Safety First: Before starting, put on your rubber gloves and safety goggles to protect yourself from harmful substances.

- Remove The Cover: Using a wrench or screwdriver, carefully remove the cover of the grease trap. Set the cover aside in a clean area.

- Check For Damage: Inspect the grease trap for any signs of damage or wear. If you notice any issues, consider contacting a professional for repairs.

Pumping Out The Grease Trap

Manual Pumping

For smaller grease traps, manual pumping is a feasible option. Here’s how to do it:

- Scoop Out The Grease: Using a small container, carefully scoop out the accumulated grease and waste. Place it in the disposal container.

- Clean The Trap: After removing the grease, use a cleaning brush to scrub the interior of the trap. This helps remove any remaining residue.

- Dispose of Waste Properly: Ensure that the waste is disposed of according to local regulations to avoid environmental contamination.

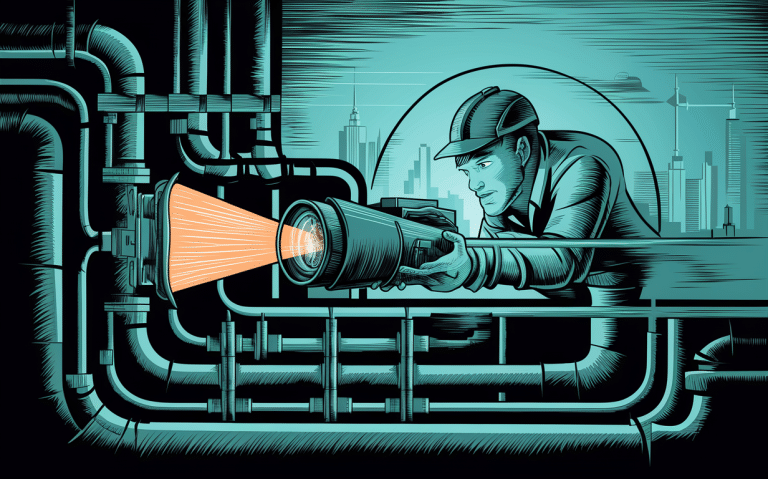

Mechanical Pumping

For larger grease traps, mechanical pumping is more efficient. Accessing and Opening the Grease Trap for Pumping involves preparing the trap for the vacuum truck to suck out the grease and waste. A professional service can handle this task, ensuring thorough cleaning and compliance with regulations.

Post-Cleaning Procedures

- Inspect The Trap: After cleaning, inspect the grease trap for any remaining residue or damage.

- Replace The Cover: Securely replace the cover, ensuring it is properly sealed to prevent leaks.

- Record Maintenance: Keep a log of the maintenance activities, including the date and observations. This helps in scheduling future cleanings and identifying potential issues early.

How Often Should You Pump Your Grease Trap?

The frequency of grease trap pumping depends on various factors, including the size of the trap and the volume of FOG generated. Typically, grease traps should be pumped every 1-3 months. Regular inspections can help determine the optimal schedule for your specific needs.

Common Issues With Grease Traps

Grease traps can encounter several issues if not maintained properly. Common problems include:

- FOG Buildup: Excessive buildup can lead to clogs and reduced efficiency.

- Foul Odors: Accumulated waste can produce unpleasant odors, affecting the kitchen environment.

- Leaks: Damaged seals or covers can cause leaks, leading to contamination and potential health hazards.

Preventing Grease Trap Issues

- Regular Maintenance: Schedule regular cleanings and inspections to keep your grease trap functioning optimally.

- Proper Disposal: Avoid pouring FOG down the drain. Use designated containers for waste disposal.

- Educate Staff: Ensure that kitchen staff understands the importance of proper grease disposal and maintenance practices.

Grease Trap Maintenance Schedule

| Trap Size (Gallons) | Frequency of Pumping |

|---|---|

| Up to 20 | Monthly |

| 20-50 | Every 2 months |

| Over 50 | Every 3 months |

Common Grease Trap Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| FOG Buildup | Infrequent pumping | Increase cleaning frequency |

| Foul Odors | Accumulated waste | Thorough cleaning |

| Leaks | Damaged seals or covers | Repair or replace components |

Signs Your Grease Trap Needs Maintenance

- Slow drainage in sinks

- Frequent clogs in the plumbing

- Unpleasant odors near the grease trap

- Visible grease or waste around the trap

Key Takeaway

Maintaining your grease trap is essential for the smooth operation of your kitchen and plumbing system. Regular pumping and cleaning prevent FOG buildup, odors, and costly repairs. By following a systematic approach and scheduling regular maintenance, you can ensure the longevity and efficiency of your grease trap system.

Conclusion

Accessing and opening your grease trap for pumping is a straightforward task if done systematically. Regular maintenance not only enhances the efficiency of your plumbing system but also prolongs the life of your grease trap.

By understanding the importance of grease trap maintenance and following the guidelines provided, you can ensure a clean and efficient kitchen environment. Remember to always follow local regulations for waste disposal and consider professional services for larger or more complex grease traps.

Keep your kitchen running smoothly with timely and effective grease trap maintenance. Call us at (888) 845-CLOG (2564) or (845) 637-3544 for a free estimate!