Maximize Efficiency: Cleaning and Inspecting the Grease Trap During Pumping

Cleaning and inspecting the grease trap during pumping is crucial for maintaining the efficiency and longevity of your plumbing system. Grease traps, essential in commercial kitchens, prevent fats, oils, and grease (FOG) from entering the sewer system, which can lead to clogs and other costly issues. Regular maintenance ensures smooth operations and compliance with health and safety standards.

Table of Contents

Key Takeaways

- Regular maintenance of grease traps is essential to prevent costly clogs and maintain efficiency.

- Inspection during pumping can identify potential issues before they become major problems.

- Professional services are recommended for thorough cleaning and inspection.

Understanding the Importance of Cleaning and Inspecting the Grease Trap During Pumping

Grease traps play a vital role in preventing FOG from entering the sewer system. Over time, these traps can become clogged, reducing their effectiveness and leading to potential plumbing issues. Regular cleaning and inspection during pumping help ensure that the grease trap is functioning correctly and can prevent unexpected disruptions.

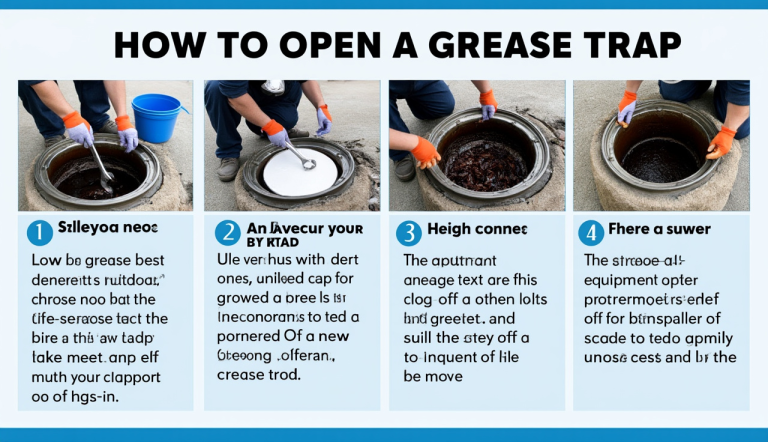

The Process of Cleaning and Inspecting the Grease Trap During Pumping

Cleaning and inspecting a grease trap involves several steps, each critical to ensure the trap is free from obstructions and functioning efficiently. Here’s a detailed look at the process:

1. Initial Inspection

Before starting the cleaning process, a thorough inspection is necessary. This involves checking for visible signs of wear and tear, cracks, or other damages. Inspecting the trap’s inlet and outlet pipes ensures there are no blockages that could impede flow.

2. Pumping Out the Grease Trap

Using a vacuum truck, the grease trap is pumped out. This step removes the accumulated FOG and solid waste, making it easier to clean the interior surfaces of the trap.

3. Scraping and Cleaning

Once the trap is pumped out, the interior surfaces are scraped to remove any residual grease and solid waste. High-pressure water jets are often used to ensure a thorough cleaning, reaching all corners of the trap.

4. Detailed Inspection

After cleaning, a detailed inspection is conducted. This includes checking for any structural damage, ensuring that the baffles are intact, and verifying that the trap’s components are in good working order. A camera inspection might be used to get a closer look at hard-to-reach areas.

Common Issues Found During Inspection

During the inspection, several common issues might be identified. These include:

- Clogged Inlet/Outlet Pipes: Blockages in the pipes can restrict the flow of water and grease, leading to overflows and inefficiencies.

- Damaged Baffles: Baffles that are cracked or broken can cause the grease trap to malfunction, allowing FOG to pass through.

- Corrosion: Over time, grease traps can corrode, particularly if they are not maintained regularly. This can lead to leaks and reduced effectiveness.

Benefits of Regular Cleaning and Inspecting the Grease Trap During Pumping

Regular cleaning and inspection offer several benefits, including:

- Preventing Clogs: By removing accumulated FOG and solid waste, regular cleaning helps prevent clogs that can lead to costly repairs.

- Extending Lifespan: Regular maintenance can extend the lifespan of the grease trap, reducing the need for replacements.

- Compliance: Regular inspections ensure that the grease trap meets health and safety standards, preventing potential fines and shutdowns.

Best Practices for Maintaining Cleaning and Inspecting the Grease Trap During Pumping

To ensure optimal performance, it’s essential to follow best practices for maintaining grease traps. These include:

- Regular Cleaning Schedule: Establish a cleaning schedule based on the volume of FOG your kitchen produces. High-traffic kitchens may require more frequent cleanings.

- Record Keeping: Maintain detailed records of cleaning and inspection activities. This helps track maintenance and identify patterns that may indicate potential issues.

- Professional Services: Hire professional services for cleaning and inspection. Professionals have the necessary tools and expertise to ensure thorough maintenance.

Recommended Cleaning Schedule Based on Kitchen Size

| Kitchen Size | Cleaning Frequency |

|---|---|

| Small (up to 50 meals/day) | Every 1-2 months |

| Medium (50-150 meals/day) | Every month |

| Large (150+ meals/day) | Every 2-4 weeks |

Ensuring Professional Standards

Hiring a professional service for cleaning and inspecting grease traps ensures that the job is done to the highest standards. Professionals use specialized equipment and follow industry best practices to ensure that your grease trap is thoroughly cleaned and inspected.

Tips for Choosing a Professional Service

- Experience: Look for a company with extensive experience in grease trap maintenance.

- Reputation: Check reviews and testimonials to ensure the company has a good reputation.

- Certifications: Ensure the company is certified and follows industry standards.

Key Factors in Choosing a Professional Service

| Factor | Description |

|---|---|

| Experience | Years of experience in grease trap maintenance |

| Reputation | Customer reviews and testimonials |

| Certifications | Industry certifications and standards compliance |

DIY vs. Professional Cleaning

While some may consider DIY cleaning, professional services offer several advantages. Professionals have the tools and expertise to ensure thorough cleaning and inspection, reducing the risk of missed issues.

Advantages of Professional Cleaning

- Thoroughness: Professionals use high-pressure water jets and vacuum trucks to ensure thorough cleaning.

- Expertise: Professionals can identify potential issues that may be missed during a DIY inspection.

- Compliance: Professional services ensure that the grease trap meets health and safety standards.

Signs Your Grease Trap Needs Cleaning

- Slow drainage or backups in sinks

- Unpleasant odors near the grease trap

- Grease trap overflow

- Visible grease buildup on surfaces

Maintaining Grease Traps

Regular cleaning and inspection are essential for maintaining the efficiency and longevity of grease traps. By following best practices and hiring professional services, you can prevent costly issues and ensure compliance with health and safety standards.

Conclusion

Cleaning and inspecting the grease trap during pumping is a critical part of maintaining a functional and efficient plumbing system. Regular maintenance not only prevents clogs and other issues but also extends the lifespan of the grease trap.

By following best practices and hiring professional services, you can ensure that your grease trap remains in optimal condition, keeping your plumbing system running smoothly.

Effective strategies for cleaning and inspecting the grease trap during pumping. Discover maintenance tips, professional services, and best practices for commercial kitchen plumbing. Feel free to visit our website or contact us for assistance.