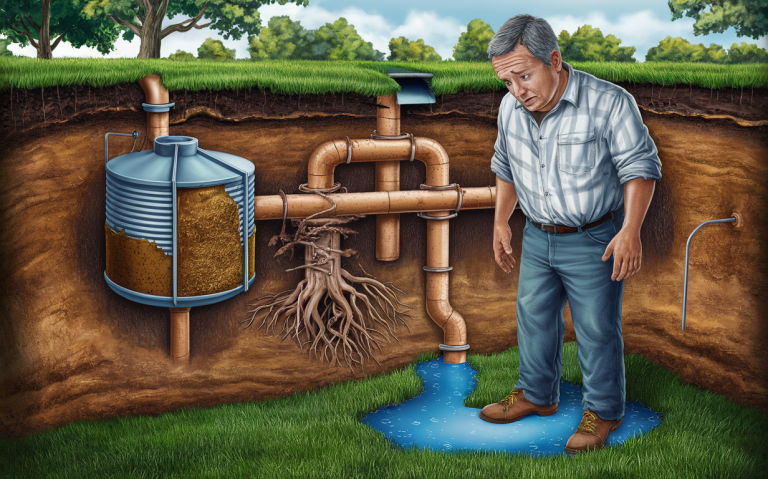

Common Lift Station Problems in Septic Systems

If you’re dealing with septic systems, you may already know that lift stations play a critical role in ensuring wastewater is effectively transported from lower to higher elevations. However, Common Lift Station Problems in Septic Systems can arise, causing significant headaches. Let’s dive into some of these issues and provide insights on how to address them.

Table of Contents

Key Takeaway

Understanding common lift station problems can help you maintain an efficient septic system and avoid costly repairs. Key issues include pump failures, float switch malfunctions, clogs, and electrical issues. Regular maintenance is crucial to prevent these problems.

What is a Common Lift Station Problems in Septic Systems?

Common Lift Station Problems in Septic Systems is an essential component of a septic system designed to move wastewater from lower to higher elevations. This is especially useful in areas where the natural topography doesn’t allow for gravity-fed drainage. The primary components of a lift station include pumps, pipes, and control panels.

Common Lift Station Problems in Septic Systems Problems

1. Pump Failures

Pump failures are among the most frequent issues in lift stations. They can result from electrical malfunctions, mechanical breakdowns, or blockages.

- Electrical Malfunctions: Over time, electrical components can wear out or corrode, leading to pump failure.

- Mechanical Breakdowns: Pumps can suffer from wear and tear, especially if they are not regularly maintained.

- Blockages: Debris and waste materials can clog the pump, causing it to overheat and fail.

2. Float Switch Malfunctions

The float switch is responsible for activating the pump when wastewater reaches a certain level. If the float switch fails, the pump may not activate, leading to potential overflow.

- Stuck Float: Debris can cause the float to stick, preventing it from rising with the water level.

- Electrical Issues: Wiring problems can prevent the float switch from signaling the pump to activate.

3. Clogs and Blockages

Clogs and blockages can occur in the pipes leading to and from the lift station. These can be caused by grease, waste, and other debris.

- Grease Buildup: Grease can solidify and clog pipes, reducing the efficiency of the lift station.

- Debris Accumulation: Foreign objects can obstruct the flow of wastewater, causing backups.

4. Alarm System Failures

Lift stations often have alarm systems to notify operators of high water levels or pump failures. Alarm system failures can result in undetected problems, leading to severe issues.

- Faulty Sensors: Sensors can fail due to wear and tear or exposure to harsh conditions.

- Communication Issues: Problems with the communication system can prevent alarms from being received.

5. Structural Damage

Structural damage to the lift station can result from environmental factors, such as soil erosion or ground movement.

- Cracks and Leaks: Over time, the structure of the lift station can develop cracks, leading to leaks.

- Foundation Shifts: Ground movement can affect the alignment of the lift station, causing operational issues.

Common Lift Station Problems in Septic Systems

| Problem | Cause | Solution |

|---|---|---|

| Pump Failure | Electrical Malfunction | Regular Electrical Inspections |

| Mechanical Breakdown | Routine Maintenance and Replacements | |

| Blockages | Regular Cleaning and Debris Removal | |

| Float Switch Failure | Stuck Float | Manual Inspection and Cleaning |

| Electrical Issues | Check Wiring and Connections | |

| Clogs and Blockages | Grease Buildup | Install Grease Traps, Regular Cleaning |

| Debris Accumulation | Implement Debris Filters | |

| Alarm System Failure | Faulty Sensors | Sensor Testing and Replacement |

| Communication Issues | Regular System Checks | |

| Structural Damage | Cracks and Leaks | Structural Repairs and Inspections |

| Foundation Shifts | Ground Stabilization Measures |

Preventative Maintenance Tips

Preventing lift station problems can save you time and money in the long run. Here are some preventative maintenance tips to keep your system running smoothly:

- Regular Inspections: Conduct routine inspections to identify potential problems early.

- Scheduled Maintenance: Follow a maintenance schedule to clean and service pumps, pipes, and control panels.

- Upgrade Components: Replace outdated components to improve efficiency and reliability.

- Monitor Alarm Systems: Ensure alarm systems are functioning correctly to alert you of any issues.

- Professional Servicing: Hire professionals for complex repairs and inspections.

Maintenance Schedule for Lift Stations

| Maintenance Task | Frequency |

|---|---|

| Pump Inspection | Bi-Monthly |

| Electrical System Check | Quarterly |

| Float Switch Inspection | Monthly |

| Pipe Cleaning | Quarterly |

| Structural Inspection | Annually |

| Alarm System Test | Monthly |

| Debris Removal | Monthly |

| Grease Trap Cleaning | Monthly |

Signs Your Lift Station Needs Attention

- Unusual noises from the pump

- Frequent tripping of circuit breakers

- Slow drainage or backups

- Foul odors near the lift station

- Alarm system alerts

Why Choose United Sewer & Septic?

At United Sewer & Septic, we specialize in addressing common lift station problems. With over 30 years of experience, our team is equipped to handle everything from routine maintenance to complex repairs. Serving Orange County, Rockland County, and Sullivan County in New York, we provide reliable and efficient service to keep your septic systems running smoothly.

Our Services Include:

- Septic tank pumping: Regular pumping to prevent overflow and maintain efficiency.

- Grease trap cleaning: Essential for food service businesses to prevent clogs.

- Septic system inspections: Detailed inspections to identify and address potential issues.

- Sewer repairs: Comprehensive repair services for clogged or broken sewer pipes.

Maintaining Your Lift Station

Maintaining your lift station is crucial for the efficient operation of your septic system. Regular Common Lift Station Problems in Septic Systems and professional servicing can prevent common Lift Station Problems in Septic Systems. By addressing issues early, you can avoid costly repairs and ensure the longevity of your system.

Remember, when it comes to septic systems, prevention is always better than cure. Don’t wait for a problem to occur before taking action. Invest in regular maintenance and keep your lift station in top condition.

Conclusion

Common lift station problems in septic systems and learn maintenance tips to prevent pump failures, clogs, and costly repairs. Contact United Sewer & Septic today to schedule your maintenance service or request an estimate.

By understanding these common lift station problems and implementing preventative measures, you can ensure the efficient operation of your septic system and avoid costly repairs. Trust United Sewer & Septic for all your septic and sewer needs, and keep your system running smoothly.