Complying with Local Regulations and Codes for Grease Trap Maintenance: Essential Tips

Complying with local regulations and codes for grease trap maintenance is crucial. Learn how to prevent blockages, avoid fines, and protect the environment.

Maintaining grease traps according to local regulations and codes is essential for businesses, especially those in the food service industry. Failure to do so can lead to costly fines, health hazards, and environmental damage.

Key Takeaway

- Grease trap maintenance is crucial for preventing blockages and ensuring efficient operation.

- Local regulations and codes mandate specific maintenance schedules and procedures.

- Proper documentation of grease trap cleaning and maintenance is often required by law.

- Hiring professional services can ensure compliance and avoid potential fines.

Why Maintaining Grease Traps is Important

Regular maintenance of grease traps is essential to prevent fats, oils, and grease (FOG) from clogging sewer systems. Compliance with local regulations helps avoid legal issues and contributes to environmental conservation.

Preventing Sewer Blockages

Grease traps capture FOG, preventing them from entering the sewer system. Blockages can lead to backups, foul odors, and expensive repairs.

Protecting the Environment

Proper grease trap maintenance prevents FOG from contaminating water bodies, which protects aquatic life and maintains water quality.

Understanding Local Regulations and Codes

Different regions have specific regulations governing grease trap maintenance. Knowing these can help ensure compliance and avoid penalties.

Common Regulatory Requirements

- Scheduled Maintenance: Most jurisdictions require regular grease trap cleaning, often every 90 days.

- Record Keeping: Businesses must maintain detailed records of grease trap maintenance.

- Disposal Methods: FOG must be disposed of according to environmental standards.

Tips for Complying with Local Regulations and Codes for Grease Trap Maintenance

Following these guidelines can help businesses stay compliant:

Regular Inspections

Schedule regular inspections to identify potential issues before they escalate. Inspections should check for:

- Accumulation of FOG

- Structural Integrity of Traps

- Proper Functioning of Components

Hiring Professional Services

Engage certified professionals for grease trap cleaning and maintenance. They are familiar with local codes and can ensure compliance.

Detailed Maintenance Procedures

Adhering to proper procedures can help maintain grease traps effectively.

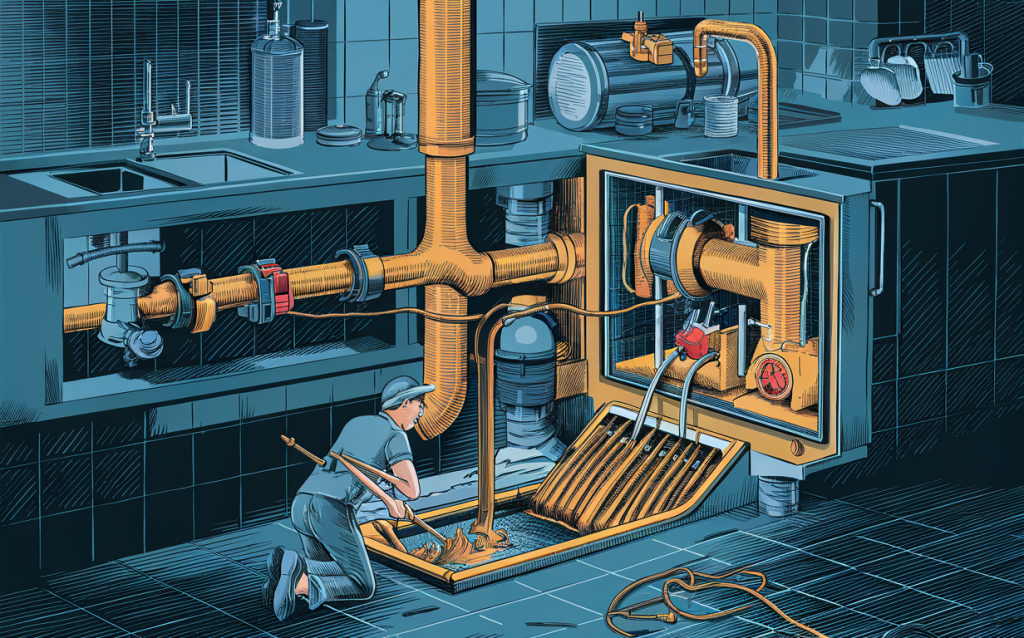

Step-by-Step Cleaning Process

- Remove the Lid: Carefully remove the grease trap lid.

- Inspect the Trap: Check for any visible damage or blockages.

- Remove Waste: Use a scoop or vacuum to remove FOG and solid waste.

- Clean the Trap: Scrub the interior with a brush and a degreasing agent.

- Rinse and Reassemble: Rinse the trap with water and reassemble.

Utilizing Technology

Modern tools like video camera inspections can identify hidden issues within the grease trap system, ensuring comprehensive maintenance.

Documentation and Reporting

Keeping accurate records is crucial for compliance.

Maintenance Logs

Maintain logs that include:

- Date of Service

- Name of Service Provider

- Results of Inspection

- Volume of FOG Removed

Reporting to Authorities

Some jurisdictions require periodic reports. Ensure reports are submitted on time and include all required information.

Common Challenges and Solutions

Businesses may face several challenges in maintaining grease traps. Here are some common issues and solutions:

Frequent Blockages

- Cause: Infrequent cleaning.

- Solution: Increase cleaning frequency and monitor FOG levels.

| Frequency (Days) | Common Issue | Solution |

|---|---|---|

| 30 | Minor Blockages | Increase Cleaning |

| 60 | Moderate FOG | Schedule Professional Service |

| 90 | Major Blockages | Immediate Maintenance |

Foul Odors

- Cause: Build-up of decaying organic matter.

- Solution: Use enzyme treatments and ensure proper ventilation.

Benefits of Proper Grease Trap Maintenance

Proper maintenance has several advantages:

- Cost Savings: Reduces the risk of expensive repairs and fines.

- Operational Efficiency: Keeps plumbing systems running smoothly.

- Health and Safety: Prevents health hazards caused by blockages and overflows.

Key Components of a Grease Trap System

Understanding the components can help in effective maintenance.

Main Parts

- Inlet and Outlet Pipes: Channels wastewater in and out.

- Baffles: Separate FOG from water.

- Trap Body: Holds the captured FOG.

- Cleanout: Provides access for cleaning and maintenance.

Importance of Each Component

Each part plays a crucial role in capturing and removing FOG. Regular checks ensure they function as intended.

Sample Maintenance Schedule

| Month | Activity | Responsible Party |

|---|---|---|

| January | Initial Inspection | Professional Service |

| February | Minor Cleaning | In-House Staff |

| March | Comprehensive Cleaning | Professional Service |

| April | Routine Inspection | In-House Staff |

| May | Minor Cleaning | In-House Staff |

| June | Comprehensive Cleaning | Professional Service |

- According to the National Restaurant Association, grease trap failures can result in costly repairs, fines, and even health code violations. (Source)

- The Environmental Protection Agency (EPA) estimates that 30% of all food service establishments have had some sort of grease trap problem. (Source)

- The frequency of grease trap cleaning depends on the size of the establishment and the amount of food waste produced. The International Kitchen Exhaust Cleaning Association (IKECA) recommends monthly cleaning for high-volume establishments. (Source)

- The cost of grease trap cleaning varies depending on the location and the size of the trap. The average cost ranges from $75 to $300 per visit. (Source)

- Failure to comply with local grease trap regulations can result in fines and even closure of the establishment. For example, in New York City, violations can result in fines up to $2,000 per day. (Source)

Key Takeaways

- Scheduled Maintenance: Follow a strict cleaning schedule.

- Use Professionals: Hire certified services to ensure compliance.

- Keep Records: Maintain detailed logs and submit required reports.

Final Thoughts

Complying with local regulations and codes for grease trap maintenance is not just a legal requirement; it’s a best practice that benefits your business, the environment, and the community. By following the guidelines outlined in this article, businesses can avoid penalties, ensure smooth operations, and contribute to a cleaner environment.

For expert grease trap maintenance services in Middletown, NY, and surrounding areas, contact United Sewer & Septic. Our professional team has the experience and equipment to keep your grease traps compliant and efficient.

By staying proactive and informed, you can easily comply with local regulations and codes for grease trap maintenance, ensuring your business runs smoothly and sustainably.

Get your free estimates now by calling us at (845) 637-3544 or (888) 845-CLOG (2564). Let us take care of everything about your sewer and septic.