Lift Station Pumping: Crucial for Septic System Health

Lift station pumping is a crucial service that keeps your property’s septic system functioning properly. If you have a septic tank that sits lower than the main sewer line or your septic drain field, you likely have a lift station that pumps the wastewater up to the proper level so it can flow out to the drain field or sewer by gravity.

Lift stations require regular maintenance and pumping to avoid backups, overflows, and costly septic system failures.

Key Takeaways on Lift Station Pumping

- Lift stations are used when a septic tank sits below the level of the main sewer line or drain field

- The lift station pumps wastewater up to the proper level so it can flow out by gravity

- Lift stations have holding tanks that collect the wastewater before it gets pumped out

- Solids can build up in the lift station tank, requiring it to be pumped out regularly

- Lift station pumping can fail if not maintained properly, leading to septic backups and overflows

- It’s important to have your lift station inspected and pumped by a professional septic service

What is a Lift Station and How Does It Work?

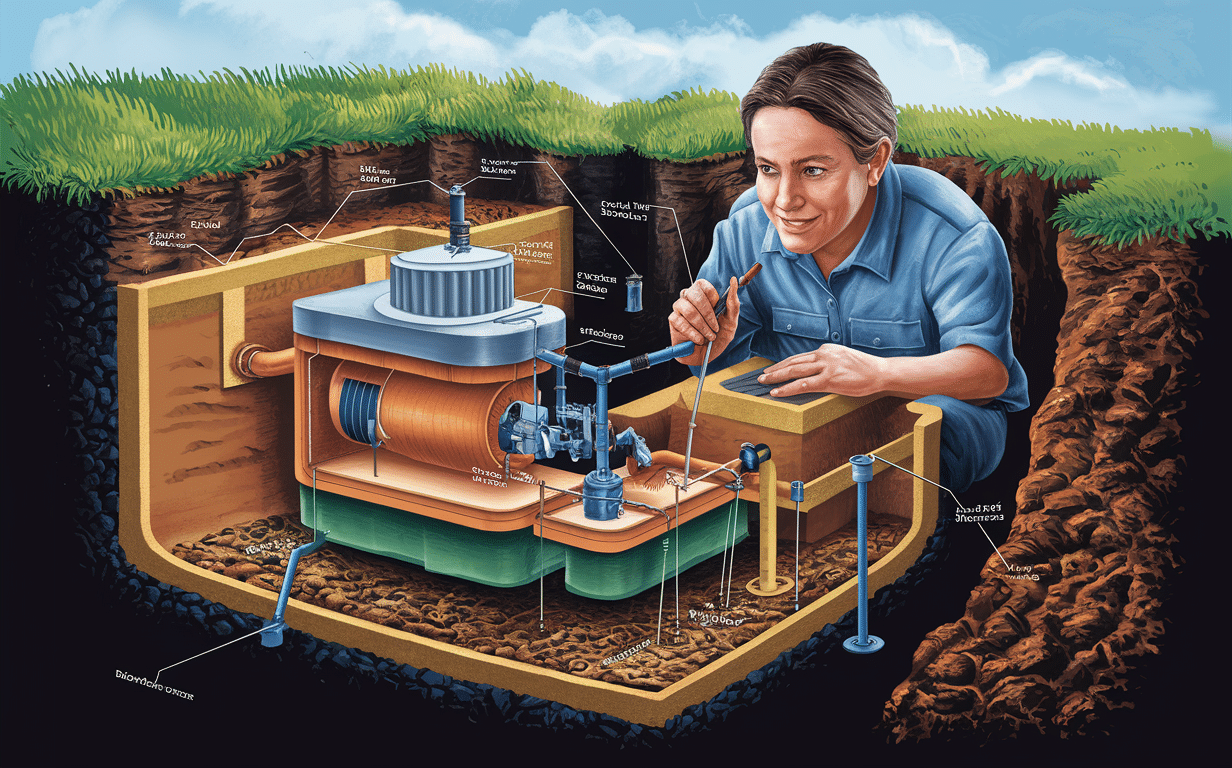

A septic lift station, also known as a pump station, is a component of some septic systems that pumps wastewater from a holding tank up to a higher elevation so that it can then flow by gravity to a septic drain field or tie into a municipal sewer main.

The lift station consists of a holding tank, usually made of concrete or fiberglass, that is installed in the ground after the septic tank. Wastewater flows from the septic tank into the lift station holding tank.

Inside the lift station tank are one or more submersible sewage pumps, along with floats or sensors that detect the level of wastewater in the tank. When the wastewater reaches a certain level, the pump automatically turns on and pumps the contents of the tank up through a pressurized pipe system.

The pressurized pipes carry the wastewater up an elevation, such as a hill, until it reaches a point where it can flow by gravity the rest of the way to the drain field or sewer connection. Without the lift station, the wastewater would be unable to flow out of the septic tank.

Why Lift Stations Need to Be Pumped Regularly

Just like with a regular septic tank, a lift station tank will gradually fill up with solids over time. Even though the lift station is primarily pumping out liquid effluent, some sludge and solid waste particles flow in from the septic tank.

As these solids accumulate in the bottom of the lift station tank, the holding capacity is reduced. If too much sludge builds up, it can cause the submersible pumps to clog or fail. It also makes the pumps have to work harder, shortening their lifespan.

To avoid these problems, septic lift stations need to be inspected and pumped out regularly by a professional septic service company that has the proper equipment. A typical lift station will need to be pumped every 2-5 years, but the frequency depends on the size of the tank, the number of building occupants, and the volume of wastewater generated.

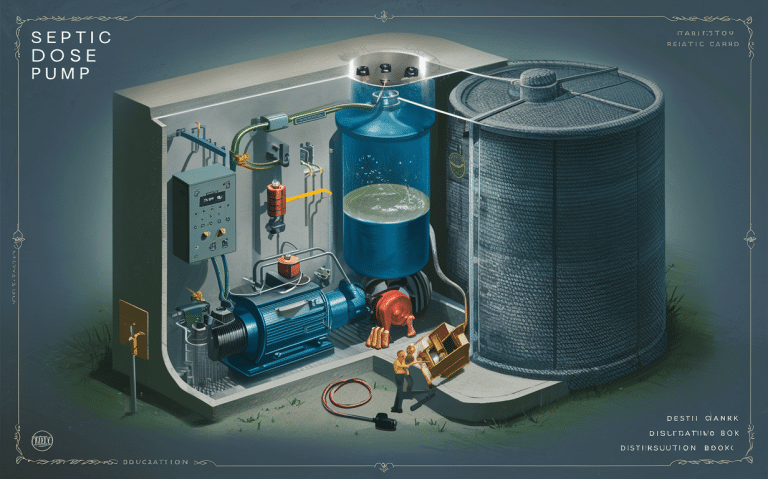

During the pumping service, the technician will open the access cover or hatch on top of the lift station and use a powerful vacuum hose to suck out all the wastewater and sludge from the tank. The inside of the tank is then cleaned and the pumps and floats are inspected to make sure they are working properly.

Common Problems with Lift Stations

There are a few common issues that can occur with lift stations if they are not regularly maintained and pumped:

| Problem | Cause | Result |

|---|---|---|

| Pump failure | Clogged impeller from solids buildup, faulty wiring, burnt out motor | Wastewater backs up into tank and possibly into building |

| Float switch malfunction | Debris interfering with float, tangled wires, faulty switch | Pump does not turn on when it should, causing overflow |

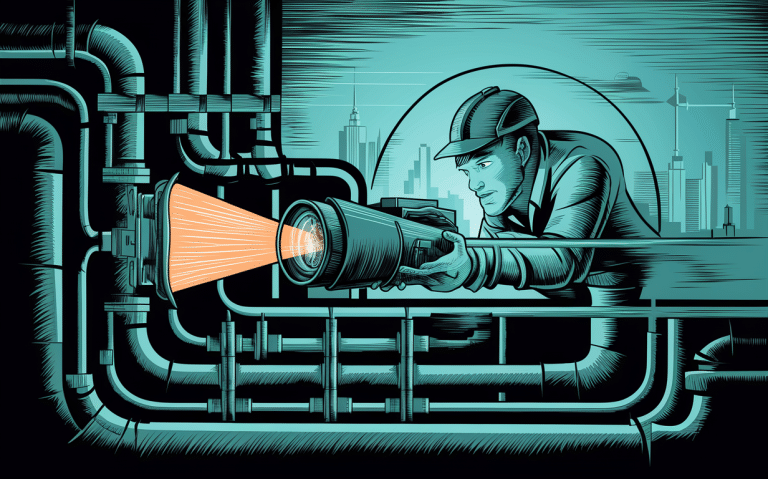

| Clogged or broken pipes | Tree roots infiltrating pipes, broken pipe connections | Wastewater leaks out underground before reaching destination |

Another problem that sometimes occurs is that the check valves on the discharge pipes fail, allowing wastewater to flow back down into the lift station tank after being pumped up. This can cause the tank to fill back up too quickly. The valves should be checked regularly.

Preventing Lift Station Problems

The best way to avoid serious issues with your lift station is to have it inspected and serviced by a professional on a regular basis. During the service, the technician should:

- Pump out and clean the tank

- Check the pump, floats, and wiring

- Inspect the piping for any cracks or leaks

- Ensure the control panel is working properly

- Look for any signs of corrosion or damage on the tank itself

Between service visits, there are a few things you can do as a property owner to help keep your lift station in good shape:

- Avoid flushing any non-biodegradable items like wipes, cotton swabs, etc. These can clog the pump.

- Don’t pour grease or oil down your drains. It congeals and causes blockages.

- Make sure the lift station access cover is closed properly and secured.

- If you notice any odd noises or smells coming from the lift station area, call for service.

- Avoid planting trees or shrubs with deep root systems near the lift station or pipes.

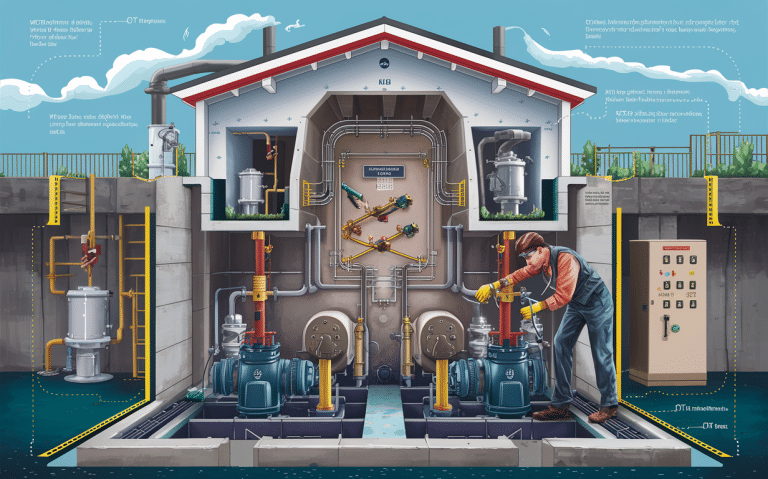

Lift Station vs Sewage Ejector Pump

Lift stations are sometimes confused with sewage ejector pumps, but they serve different purposes. A sewage ejector pump is used when a bathroom, laundry room or other fixture is located below the level of the main sewer line exiting the building. The ejector pump collects the wastewater from the fixture(s) in a small holding tank called a basin and grinds it up before pumping it up to the sewer line.

In contrast, a lift station pumps wastewater from the septic tank up to a drain field or municipal sewer connection. They are much larger systems located outside the building after the septic tank.

The Importance of Professional Lift Station Pumping

Attempting to service or pump your lift station on your own is never advisable. Exposure to raw sewage is a health hazard and requires protective gear and equipment. Septic companies are trained in the proper safety procedures and have the industrial-grade pumps and hoses needed to thoroughly clean a lift station.

Additionally, lift stations contain electrical components and wiring that requires professional knowledge to inspect and repair. Improperly working on a lift station could lead to electrocution or pump failures that cause sewage backups into your property.

When hiring a septic company to maintain your lift station, make sure they are licensed and insured for this type of work. Ask about their experience with lift stations and how often they recommend having yours pumped based on its specifications and your household size. Many septic companies offer preventative maintenance contracts where they will inspect and service your lift station on a regular schedule so you don’t have to worry about remembering to do it.

Lift Station Pumping and Septic System Health

Your lift station is a critical component of your septic system if your property’s elevation requires wastewater to be pumped up to the drain field or sewer. Just like your septic tank, the lift station needs to be regularly cleaned and maintained to remove the solid waste that builds up in it over time.

Neglecting lift station pumping can result in clogged pipes, pump burnout, and complete system failures that can be messy and expensive to repair. Lift station tanks that overfill can cause smelly wastewater to back up into your yard or even into your building’s drains.

Having your lift station inspected and pumped by a professional septic service on a regular basis is the best way to avoid serious problems and keep your entire septic system in proper working order for the long term. If you can’t remember the last time your lift station was pumped, it’s probably time to schedule a service!

Key Takeaways

- Lift stations are a critical component of many septic systems, used to pump wastewater to a higher elevation

- Solids gradually accumulate in lift station tanks and must be pumped out every few years

- Clogged pumps, broken floats, and leaking pipes are common lift station problems

- Regular inspection and pumping by a septic professional is key to preventing lift station failures

- Neglecting lift station maintenance can lead to messy, costly sewage backups and septic system damage

If you’d like to receive a quote for septic lift tank please give us a call (888) 845-2564 or fill out our contact form and we’ll get right back to you.