Reliable Lift Station Repair and Upgrade Services for Efficiency

Commercial properties with wastewater management systems often rely on lift stations to ensure efficient waste removal. Lift stations pump wastewater from lower to higher elevations, making it crucial to maintain their functionality. If your lift station is malfunctioning or outdated, it might be time for a repair or upgrade.

Key Takeaway

Lift station repair and upgrade services are essential for maintaining the efficiency, reliability, and compliance of commercial wastewater systems. A functional lift station prevents sewage backups, minimizes downtime, and ensures environmental regulations are met.

Investing in professional repair and upgrade services can significantly improve the lifespan and performance of your wastewater system.

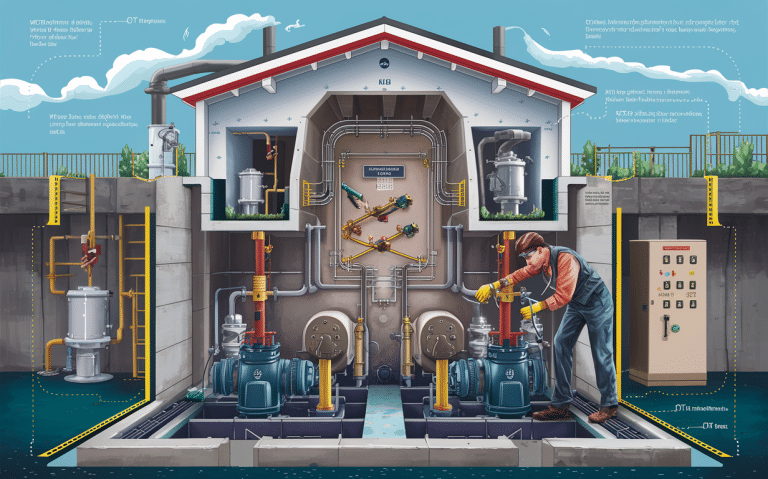

Understanding Lift Stations: What They Do and Why They Matter

Lift stations play a pivotal role in wastewater management by pumping sewage from lower to higher elevations. This is particularly critical in commercial properties where gravity alone cannot facilitate waste flow due to structural layouts.

- Wastewater Collection: Lift stations collect wastewater from various sources within the property.

- Pumping Mechanism: They pump the collected wastewater to higher elevations or treatment facilities.

- Control Systems: Lift stations are equipped with control panels that regulate the pumps and alert operators during malfunctions.

Common Issues with Lift Stations

Lift stations can encounter several issues that necessitate repair or upgrades. The most common problems include:

- Pump Failure: Mechanical wear and tear can lead to pump failure, affecting the station’s functionality.

- Clogging: Debris and grease buildup can clog the system, causing backups.

- Electrical Failures: Power surges or electrical malfunctions can disrupt the control systems.

- Corrosion: Constant exposure to wastewater can corrode the pumps and piping, compromising the system.

Signs Your Lift Station Needs Repair or Upgrade

Recognizing the signs of a failing lift station can save you from more significant problems down the line. Here are some indicators:

- Frequent Alarms: If your control panel frequently signals alerts, it’s a sign that something isn’t working correctly.

- Unusual Noises: Grinding or rattling noises from the pump could indicate mechanical issues.

- Slow Drainage: If wastewater isn’t draining as quickly as it should, your lift station might be underperforming.

- Odors: Persistent foul smells could signify a clog or malfunction within the system.

- Rising Utility Bills: Unexpected increases in your utility bills might be due to inefficient pump operation.

The Importance of Professional Lift Station Repair and Upgrade Services

Hiring professionals for lift station repair and upgrade services ensures that your system runs efficiently and adheres to regulatory standards. Here’s why you need expert services:

- Technical Expertise: Professional technicians have the knowledge and tools to diagnose and fix complex issues.

- Compliance: Ensure your system meets all environmental and safety regulations.

- Efficiency: Professional repairs and upgrades can enhance the performance and lifespan of your lift station.

- Emergency Response: Experts can provide quick solutions during emergencies, minimizing downtime.

Comprehensive Lift Station Services

Our company offers a range of lift station repair and upgrade services tailored to meet the needs of commercial properties:

Emergency Repair Services

Emergencies can occur at any time, causing significant disruptions. Our team provides 24/7 emergency lift station repairs to address urgent issues swiftly.

Routine Maintenance and Inspection

Regular maintenance is key to preventing breakdowns. Our routine maintenance services include:

- Pump and Motor Inspection: Checking for wear and tear.

- Electrical System Testing: Ensuring all electrical components are functioning correctly.

- Debris Removal: Cleaning out debris and grease buildup.

- Control Panel Calibration: Adjusting settings for optimal performance.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Pump Inspection | Quarterly | High |

| Electrical Testing | Bi-annual | Medium |

| Debris Removal | Monthly | Critical |

| Control Calibration | Annually | High |

Lift Station Upgrades

If your lift station is outdated, upgrading to modern systems can offer several benefits:

- Advanced Technology: Upgraded systems come with advanced control panels and energy-efficient pumps.

- Enhanced Capacity: Newer systems can handle higher volumes of wastewater.

- Improved Reliability: Modern components are more durable and less prone to failure.

Grease Trap and Interceptor Cleaning

For commercial kitchens and food services, grease traps can clog lift stations if not cleaned regularly. Our scheduled grease trap cleaning services ensure your lift station remains clog-free.

Understanding the Cost of Lift Station Repairs and Upgrades

The cost of repairs and upgrades can vary based on several factors:

- Extent of Repairs: The more severe the damage, the higher the cost.

- System Size: Larger systems require more resources and time.

- Type of Upgrade: Technological upgrades might be more expensive but offer long-term savings.

Cost-Benefit Analysis

Investing in professional repair and upgrade services can be cost-effective in the long run. Here’s a cost-benefit analysis to consider:

| Factor | Without Maintenance | With Professional Services |

|---|---|---|

| Repair Frequency | High | Low |

| Downtime | Significant | Minimal |

| Emergency Costs | High | Controlled |

| System Lifespan | Short | Long |

Choosing the Right Service Provider

When selecting a service provider, consider the following:

- Experience: Choose a company with extensive experience in lift station repairs and upgrades.

- Licensing and Certification: Ensure they are licensed and certified to perform the necessary work.

- Customer Reviews: Look for positive reviews and testimonials from previous clients.

Key Benefits of Upgrading Your Lift Station

Upgrading your lift station offers several benefits:

- Increased Efficiency: Modern systems use less energy and operate more efficiently.

- Reduced Maintenance Costs: Newer systems require less frequent repairs and maintenance.

- Compliance: Upgraded systems adhere to the latest environmental and safety standards.

- Enhanced Performance: Improved reliability and capacity for handling increased wastewater volumes.

Frequently Asked Questions

Q: How often should lift stations be inspected? A: Lift stations should be inspected quarterly to ensure optimal performance.

Q: What are the main components of a lift station? A: The main components include pumps, control panels, alarm systems, and piping.

Q: Can lift station upgrades be done without disrupting operations? A: Yes, upgrades can be planned and executed with minimal disruption to your operations.

Q: What is the lifespan of a typical lift station? A: The lifespan of a lift station can range from 10 to 30 years, depending on maintenance and usage.

Practical Tips for Maintaining Your Lift Station

- Regular Inspections: Schedule regular inspections to catch issues early.

- Professional Servicing: Use professional services for repairs and maintenance.

- Debris Management: Keep the area around the lift station free from debris.

- Monitor Alarms: Pay attention to alarms and address issues promptly.

Lifespan of Lift Station Components

| Component | Average Lifespan |

|---|---|

| Pumps | 5-10 years |

| Control Panels | 10-15 years |

| Piping | 20-30 years |

| Alarms | 5-10 years |

Why United Sewer & Septic?

At United Sewer & Septic, we bring over 30 years of experience in the septic and sewer industry. Our team is equipped with state-of-the-art tools and extensive knowledge to handle all your lift station needs.

Whether you need emergency repairs, routine maintenance, or system upgrades, we are here to ensure your wastewater management system runs smoothly.

Give us a call today at (888) 845-CLOG (2564) to schedule your lift station service and experience the difference professional care can make.